|

|

|

|

|

FME【十周年精粹】一 | 选择性激光熔化与传统制造工艺在金属零件制造中的微观结构和性能差异综述 |

|

|

论文标题:Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review

期刊: Frontiers of Mechanical Engineering

作者:Bo SONG, Xiao ZHAO, Shuai LI, Changjun HAN, Qingsong WEI, Shifeng WEN, Jie LIU, Yusheng SHI

发表时间:14 Jul 2015

DOI:10.1007/s11465-015-0341-2

微信链接:点击此处阅读微信文章

亲爱的读者朋友们,此前我们已推送《FME十周年论文精粹》的前言内容,带大家初步触摸了FME十年间的前沿成果脉络与学术精华,接下来公众号将开启「十周年精粹」系列 —— 我们会遵循论文集的篇章逻辑,对其中精选的12篇代表性论文依次推送。今天,「十周年精粹」的第一期正式与大家见面。

文章亮点 / Highlights

选择性激光熔化(SLM)作为增材制造技术的一种,在金属零件制备领域应用广泛。该技术以粉末为原料,通过逐层加工直接制造零件,与其他增材制造技术相比,具备制造复杂结构零件且三维精度高的优势,因而可应用于航空航天、医疗、模具等行业。然而,选择性激光熔化与铸造、锻造等传统制造方法存在显著差异,尤其在产品的微观结构和性能方面区别明显。

华中科技大学材料成形与模具技术国家重点实验室宋波等人在《Frontiers of Mechanical Engineering》2015年第10卷第2期发表了题为“Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review”的综述论文。本文结合华中科技大学快速制造中心(HUST-RMC)的研究成果,并对比其他已报道研究的特征,综述了选择性激光熔化技术制备金属材料的相关研究,阐述了该技术下零件的微观结构、性能、尺寸精度及应用,旨在为金属零件制造领域的技术选择与创新提供参考,推动选择性激光熔化技术在更多高端制造领域的应用与发展。

文章最后指出,选择性激光熔化技术虽在复杂结构、难加工材料零件制造等方面展现出独特优势,但仍面临微观缺陷控制、性能改善、表面质量提升等挑战。未来需进一步优化工艺参数、完善材料体系,以充分发挥该技术的潜力,为金属零件制造行业的进步贡献力量。

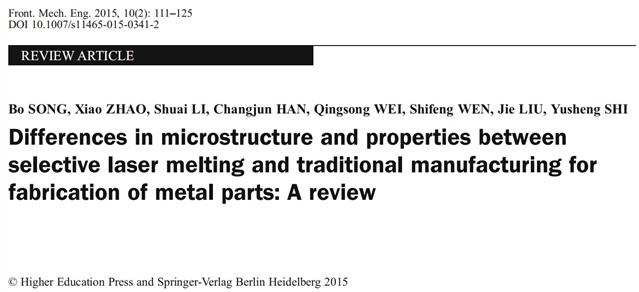

SLM样品中微晶粒边界(MPBs)的扫描电子显微镜图像。(a)与激光扫描方向平行的截面上的微晶粒边界;(b)与扫描方向垂直的截面形态;(c)“轨迹-轨迹”型微晶粒边界形态

摘要 / Abstract

Selective laser melting (SLM), as one of the additive manufacturing technologies, is widely investigated to fabricate metal parts. In SLM, parts are manufactured directly from powders in a layer-by-layer fashion; SLM also provides several advantages, such as production of complex parts with high three-dimensional accuracy, compared with other additive manufacturing technologies. Therefore, SLM can be applied in aeronautics, astronautics, medicine, and die and mould industry. However, this technique differs from traditional methods, such as casting and forging; for instance, the former greatly differs in terms of microstructure and properties of products. This paper summarizes relevant studies on metal material fabrication through SLM. Based on a work completed in Huazhong Univ. Sci Tech., Rapid Manuf. Center (HUST-RMC) and compared with characteristics described in other reported studies, microstructure, properties, dimensional accuracy, and application of SLM are presented.

引用信息 / Citation Information

Bo SONG, Xiao ZHAO, Shuai LI, Changjun HAN, Qingsong WEI, Shifeng WEN, Jie LIU, Yusheng SHI. Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review. Front. Mech. Eng., 2015, 10(2): 111–125

https://doi.org/10.1007/s11465-015-0341-2

扫描二维码阅读原文

精彩推荐

1.重磅特别推荐|FME十周年论文精粹上线!

2.FME文章速览 | 不同冷却条件下铣削超高强度钢时刀具与工件界面摩擦学行为研究

3.FME文章荐读 | 改进的最小方差无失真响应谱方法在叶尖定时中实现高效且鲁棒的非均匀欠采样频率识别

4.FME文章速览 | 一种考虑蠕墨铸铁演化过程中的应变硬化和储存能效应的新应力-应变关系建模方法

5.工程开发前沿(Ⅲ):低空无人飞行器综合探测技术 | 2024机械与运载工程领域重点解读

特别声明:本文转载仅仅是出于传播信息的需要,并不意味着代表本网站观点或证实其内容的真实性;如其他媒体、网站或个人从本网站转载使用,须保留本网站注明的“来源”,并自负版权等法律责任;作者如果不希望被转载或者联系转载稿费等事宜,请与我们接洽。