流化床中的颗粒增大控制与建模在制药和食品工业中至关重要,但在工业催化剂制备与成型领域仍发展不足。

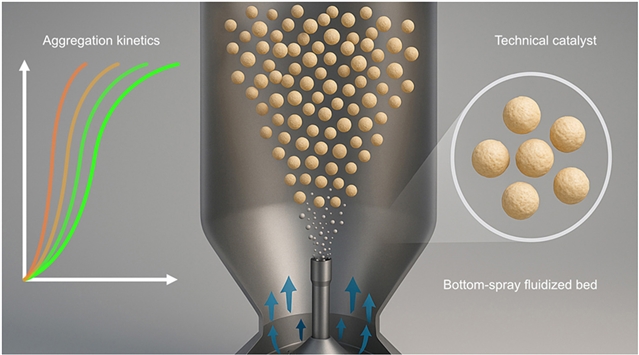

研究组采用多种建模方法解析聚集动力学:单路径与双路径群体平衡方程建模及机器学习方法。这些模型基于底喷流化床的大量实验结果进行训练,采用了符合实际工业催化剂条件的原料体系:ZSM-5分子筛、膨润土和氧化铝。优化模型采用双路径群体平衡方程,通过设定两个不同的碰撞效率参数来分别描述早期与晚期生长动力学,涵盖成核、晶种形成、晶种聚集和层状生长全过程。基于该模型,研究组探讨了实际工业催化剂的造粒与团聚动力学,并通过多个形态定制案例研究(50、100及200 μm颗粒)在优化条件下的受控制备(即目标粒径范围内最大化产率)进行了验证。

附:英文原文

Title: Aggregation kinetics of technical catalysts in a spray-fluidized bed

Author: Pedro Castao a d

Issue&Volume: 2026/01/14

Abstract: Size enlargement control and modeling in fluidized beds are crucial in the pharmaceutical and food industries but remain underdeveloped for technical catalyst formulation and shaping. This work uses different modeling approaches to understand aggregation kinetics: single- and two-pathway population balance equation (PBE) modeling and machine learning. These models are trained on a large dataset of experimental results from a bottom spray-fluidized bed, using realistic technical catalyst conditions and ingredients: ZSM-5 zeolite, bentonite, and alumina. Our optimized model is based on a two-pathway PBE with two distinct collision efficiencies for early- and late-stage growth dynamics across nucleation, seed formation, seed aggregation, and layered growth. With this model, we discuss the granulation and agglomeration dynamics of realistic technical catalysts and study the controlled shaping of several case studies with tailored morphologies (50, 100, and 200 μm pellets) under optimized conditions (i.e., maximum yield within the desired particle range) as validation.

DOI: 10.1016/j.partic.2026.01.005

Source: https://www.sciencedirect.com/science/article/abs/pii/S1674200126000258

Particuology:《颗粒学报》,创刊于2003年。隶属于爱思唯尔出版集团,最新IF:3.5

官方网址:https://www.sciencedirect.com/journal/particuology

投稿链接:https://www2.cloud.editorialmanager.com/partic/default2.aspx