|

|

|

|

|

FME | 综述文章:超精密加工与3D打印——现状、机遇和未来展望 |

|

|

论文标题:3D printing for ultra-precision machining: current status, opportunities, and future perspectives

期刊: Frontiers of Mechanical Engineering

作者:Tao HE , Wai Sze YIP , Edward Hengzhou YAN , Jiuxing TANG , Muhammad REHAN , Long TENG , Chi Ho WONG , Linhe SUN , Baolong ZHANG , Feng GUO , Shaohe ZHANG , Suet TO

发表时间:15 Aug 2024

DOI:10.1007/s11465-024-0792-4

微信链接:点击此处阅读微信文章

香港理工大学的Wai Sze YIP、Suet TO研究团队在《Frontiers of Mechanical Engineering》2024年8月刊发表了题为“3D printing for ultra-precision machining: current status, opportunities, and future perspectives”的综述型论文,文章概述了用于3D打印的超精密加工(UPM)技术的现状,分析了将UPM与3D打印相结合的好处,并进一步讨论了将这两种先进制造技术融入潜在行业的未来前景。

研究背景

UPM和3D打印是两项极具潜力的新兴技术,UPM遵循减材制造原理,3D打印基于快速成型和增材制造原理。然而,3D打印技术虽然有一定的优势,但在精度、表面质量等方面仍存在不足,因此提出将3D打印和UPM技术相结合。本文描述了UPM和3D打印技术的突出特点和来源。详细阐述了两种技术结合的优势和应用,并对这种技术结合的前瞻性发展进行了评估。研究的目的是利用先进制造和加工技术的能力来推动行业进步并弥合相关研究领域的现有差距。

主要研究内容

UPM基于减材制造原理,通过铣削、研磨和抛光等方法实现纳米级加工精度,广泛应用于激光、光学、电子等领域,但存在材料去除率低和可持续性问题。其使用的刀具如金刚石刀具,对加工质量至关重要,且表面生成机制受多种因素影响,模拟建模和人工智能技术可辅助优化加工过程。

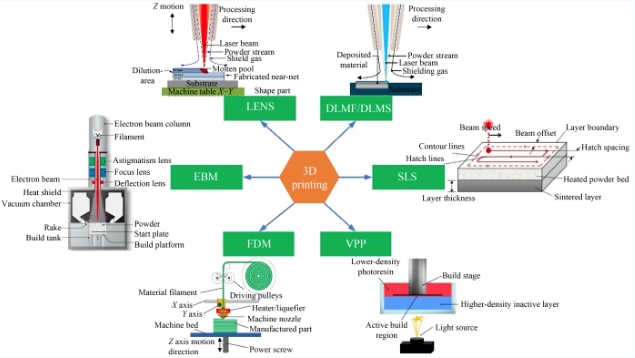

3D打印基于增材制造原理,能制造复杂结构零件,具有材料浪费少、成本效益高等优点,但存在精度、表面质量和材料等方面的挑战。该技术分为挤出式和基于激光的增材制造等类型,在航空航天、生物医学等领域有广泛应用,也可用于传统加工,如制造模具、复杂结构件等。

3D打印在工业应用中存在局限性,如打印材料缺陷、表面质量差、尺寸精度受多种因素影响等,在微尺度制造商业化方面也面临挑战。不同的3D打印技术各有优缺点,如选择性激光烧结(SLS)设备和材料成本高,熔融沉积建模(FDM)有明显打印痕迹等。

图 1 当前主流的3D打印技术

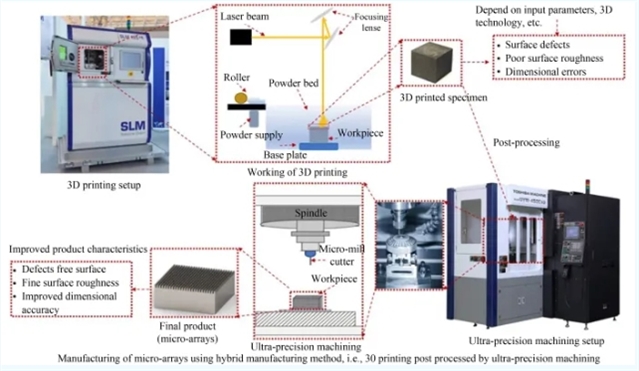

3D打印技术可制造多种材料的切削刀具,如硬质合金、陶瓷和金刚石刀具等,具有独特结构和性能优势,能提高加工性能,在UPM中有市场潜力。对3D打印部件进行UPM可解决其表面质量、尺寸精度和机械性能等问题,在模具、光学、机械和微电子等领域有重要应用,能提升产品质量和性能。UPM后处理可改善3D打印部件的表面光洁度、尺寸精度和材料性能,在生物医学领域,两者结合对实现临床应用潜力至关重要。

图2 提出的用于微结构制造的UPM和3D结合打印

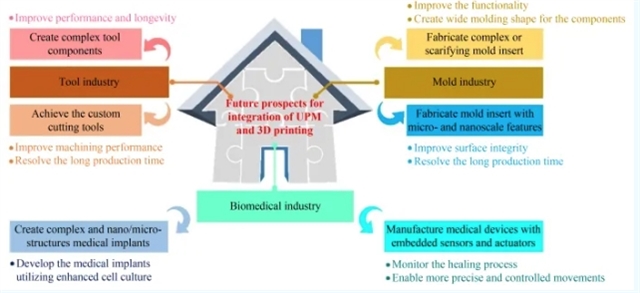

UPM与3D打印技术的结合在工具、模具和生物医学等行业有广阔前景,可提高工具性能和定制性、改善模具功能和表面完整性、推动医疗设备研发。未来研究应聚焦于提高智能3D打印和智能UPM技术水平和有效性,实现两者更深度融合,以拓展应用领域,促进工业生产和加工效率提升。

图3 3D打印和UPM结合的未来前景

原文信息

3D printing for ultra-precision machining: current status, opportunities, and future perspectives

Tao HE, Wai Sze YIP, Edward Hengzhou YAN, Jiuxing TANG, Muhammad REHAN, Long TENG, Chi Ho WONG, Linhe SUN, Baolong ZHANG, Feng GUO, Shaohe ZHANG, Suet TO

Abstract:

Additive manufacturing, particularly 3D printing, has revolutionized the manufacturing industry by allowing the production of complex and intricate parts at a lower cost and with greater efficiency. However, 3D-printed parts frequently require post-processing or integration with other machining technologies to achieve the desired surface finish, accuracy, and mechanical properties. Ultra-precision machining (UPM) is a potential machining technology that addresses these challenges by enabling high surface quality, accuracy, and repeatability in 3D-printed components. This study provides an overview of the current state of UPM for 3D printing, including the current UPM and 3D printing stages, and the application of UPM to 3D printing. Following the presentation of current stage perspectives, this study presents a detailed discussion of the benefits of combining UPM with 3D printing and the opportunities for leveraging UPM on 3D printing or supporting each other. In particular, future opportunities focus on cutting tools manufactured via 3D printing for UPM, UPM of 3D-printed components for real-world applications, and post-machining of 3D-printed components. Finally, future prospects for integrating the two advanced manufacturing technologies into potential industries are discussed. This study concludes that UPM is a promising technology for 3D-printed components, exhibiting the potential to improve the functionality and performance of 3D-printed products in various applications. It also discusses how UPM and 3D printing can complement each other.

Cite this article

Tao HE, Wai Sze YIP, Edward Hengzhou YAN, Jiuxing TANG, Muhammad REHAN, Long TENG, Chi Ho WONG, Linhe SUN, Baolong ZHANG, Feng GUO, Shaohe ZHANG, Suet TO. 3D printing for ultra-precision machining: current status, opportunities, and future perspectives. Front. Mech. Eng., 2024, 19(4): 23

https://doi.org/10.1007/s11465-024-0792-4

扫描二维码阅读全文

精彩推荐

1. 2024年度精彩盘点 | FME

2. 我们的2024 | FME期刊封面故事精彩回顾

3. FME期刊内容摘要 | 2024年第六期 (Dec. 2024, Volume 19 Issue 6)

4. FME期刊内容摘要 | 2024年第五期 (Oct. 2024, Volume 19 Issue 5)

5. 均布圆孔对超声装备振动特性的影响 | FME文章推荐

特别声明:本文转载仅仅是出于传播信息的需要,并不意味着代表本网站观点或证实其内容的真实性;如其他媒体、网站或个人从本网站转载使用,须保留本网站注明的“来源”,并自负版权等法律责任;作者如果不希望被转载或者联系转载稿费等事宜,请与我们接洽。